Rehaki s.r.o. - Ivan Rehak

20+ years | 19 countries | Operational Excellence

Lean Consultant | Lecturer | Conference Speaker |

Interim Manager | Manufacturing Process Improvement

- I specialize in providing innovative solutions for lean manufacturing and operational efficiency.

- I help businesses optimize production processes, reduce waste, and improve overall productivity.

-

I support organizations in training teams, fostering a culture of continuous improvement,

and achieving sustainable results in their operations.

Rehaki s.r.o.

Ivan Rehak

20+ years | 19 countries | Operational Excellence

Lean Consultant | Lecturer | Conference Speaker |

Interim Manager | Manufacturing Process Improvement

- I specialize in providing innovative solutions for lean manufacturing and operational efficiency.

- I help businesses optimize production processes, reduce waste, and improve overall productivity.

-

I support organizations in training teams, fostering a culture of continuous

improvement, and achieving sustainable results in their operations.

LEAN tools training

„Join the LEAN tool training with me! 👌 I will be your guide to smooth and effective process improvement. Gain practical skills, inspiration and concrete steps to transform your business. 🏆 Don’t wait, start your journey to excellence now! 🌟“

Consultation 1:1

„Try a 1:1 consultation with a LEAN management expert!

podcasts - NEW

Listen to interviews with people from the industry in the podcast Don't be silent, BE LEAN! There are over 70 interviews.

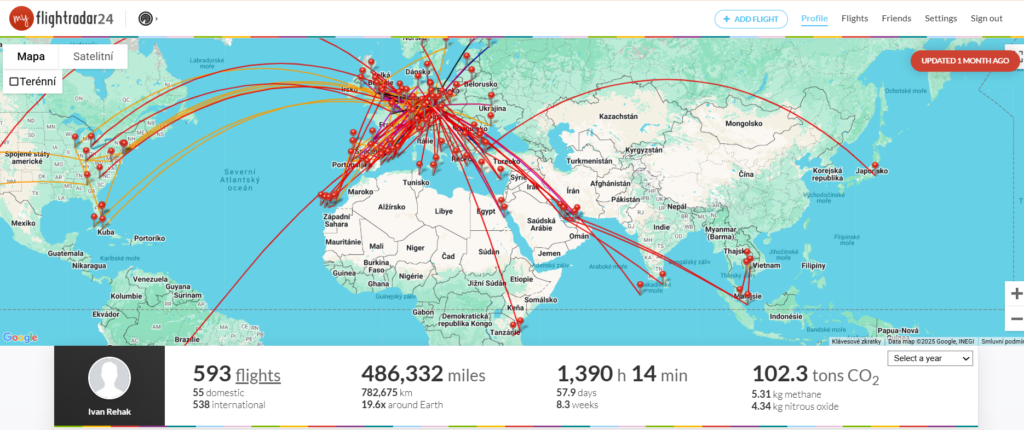

I combine my passion for travel and improvement

Over the past 20 years, I have helped manufacturing companies in 19 countries improve their processes. I will be happy to put all this experience to good use when working with you.

Thanks to this, I can identify with German precision the areas where you have potential for improvement and adjust them to run like a Swiss watch. I will explain everything to your employees and the new system will not be a Spanish village for them. Every look at your financial results will put an American smile on your face.

Get your business in shape

Entry prices are only going up now. So it’s a good time to improve processes that will significantly reduce your expenses without limiting your business operations.

I can define the strategic areas where you need to improve and suggest what steps you can take to fix it.

My work motto is:

„Veni, Vidi, Vici – I came, I saw, I improved.“ Convince yourself of its truth.

Please contact me if:

- You are the owner or director of a manufacturing company and you feel like your business is getting over your head.

- You are growing and challenges are jumping from all sides. Or a system that's been pretty good suddenly doesn't work.

- Important information is lost in the communication and the flow of supply is hindered.

- You are an individual or freelancer and want to improve some work processes, but you don't know how to start.

I'll help you if:

- Your company is no longer profitable.

- You perceive that there is a poor transfer of information among workers.

- In teams you hear blaming each other, shifting the responsibilities.

- People in your structure have inaccurate or no definition of authority, responsibility and agenda.

- The agenda of individual employees is too dependent on specific persons and thus almost unpredictable.

WHAT MY STRATEGY INVOLVES

Vision and values

- be a valuable discussion partner for companies with sufficient insight into improvement issues

- help companies build stronger, more engaged teams with demonstrable improvements in KPIs

- helping individuals to improve their processes

Draft objectives

- based on a detailed analysis of your production processes and company culture, we will work together to create an action plan with clearly defined priorities

Meeting objectives

- training of individual CI tools (in-house)

- Kaizen events / workshops on a topic according to your needs (production, logistics, HR, maintenance)

- longer-term projects with clearly defined exit criteria for success

THE 4 PILLARS OF MY KNOW-HOW

Expertise

Experience

I’ve worked in a facility of 50 employees up to 1100 – this has given me valuable experience of how much impact the number of employees has on the dynamics and culture of a company.

Intuition

Common sense

SUCCESS STORIES - CASE STUDIES

Workshops (3-5 days)

- Increase in OEE / productivity by collecting and analyzing data from MES (DMAIC method) - increase in OEE 15%, cost avoidance investment of 2mil EUR on a new machine line

- VSM (Value Stream Mapping) = Value Stream Mapping - 29% reduction in inventory value

-

Mapping of handling in the plant - savings of 60k EUR -

3-10% of costs - Introduction of SMED method to speed up order / tool changeover - 20-50% faster changeover

- Brainstorming: create a "bucket list" of 160 improvement potentials - find a potential of 80k-200k EUR in each plant (3-10% of costs)

Projects (1-6 months)

-

Creating a continuous improvement (CI) manual for each employee and involving all staff in the process -

reducing waste and costs in all departments - Increasing the share of recycled material from 40 to 95% (3-month project) - savings of 80k EUR

- Implementation of the 5S method throughout the plant for a clean and safe environment (6-month project) - Increased safety, awareness and knowledge of continuous improvement tools - Reduced costs

- Reduction of variability in the release varnish application process (6-month project) - 12% reduction in grammage, savings of 200k EUR

Workshops (3-5 days)

- Increase in OEE / productivity by collecting and analyzing data from MES (DMAIC method) - increase in OEE 15%, cost avoidance investment of 2mil EUR mil on a new machine line

- VSM (Value Stream Mapping) = Value Stream Mapping - 29% reduction in inventory value

- Mapping of handling in the plant - savings of 60k EU -> EUR 3-10% of costs - 3-10% of costs

- Introduction of SMED method to speed up order / tool changeover - 20-50% faster changeover

- Brainstorming: create a "bucket list" of 160 improvement potentials - find a potential of 80k-200k EUR in each plant (3-10% of costs)

Projects (1-6 months)

-

Creating a continuous improvement (CI) manual for each employee and involving all staff in the process -

reducing waste and costs in all departments - Increasing the share of recycled material from 40 to 95% (3-month project) - savings of 80k EUR

- Implementation of the 5S method throughout the plant for a clean and safe environment (6-month project) - Increased safety, awareness and knowledge of continuous improvement tools - Reduced costs

- Reduction of variability in the release varnish application process (6-month project) - 12% reduction in grammage, savings of 200k EUR

REFERENCE

COOPERATION WITH IMPORTANT COMPANIES

video interviews

Get a valuable discussion partner.

A partner with sufficient insight into the improvement issues and distance from your company.

Podcast from 5.5.2023 – You will discover:

2. Processes in business

3. Video – Summary of the CI Conference BeExcellent

podcasts

Listen to the entire podcast:

CONTACT

- Is your business getting over your head?

- Do you need to consult some processes in your company that are not optimally set up?

- Do you need to involve employees at all levels from production operators to managers in the improvement process?

I’m here for you. Contact me.

- Rehaki s.r.o.

- +420 601 130 679

- ivan@rehaki.com

- YouTube

-

Address:

Tyršova 873 street

Rychnov u Jablonce nad Nisou

Czech Republic - ID: 23578891

- Registered in the Trade Register